Introduction (Supply Chain Management):

In the dynamic and interconnected world of business, Supply Chain Management (SCM) plays a pivotal role in ensuring the smooth flow of goods and services from manufacturers to end consumers. Within SCM, one key concept that has gained prominence in recent years is Strategic Sourcing. This approach goes beyond the traditional procurement model, aiming to optimize the procurement process, reduce costs, and enhance overall supply chain efficiency. In this blog post, we delve into the intricacies of strategic sourcing and its significance in modern supply chain management.

Defining Strategic Sourcing in Supply Chain:

Strategic sourcing can be defined as a systematic and collaborative process of identifying, evaluating, and selecting suppliers to enhance the overall performance of an organization’s supply chain. Unlike traditional procurement practices that focus solely on cost, strategic sourcing takes a holistic approach, considering factors such as quality, reliability, innovation, and risk management.

Key Components of Strategic Sourcing in Supply Chain:

Supplier Relationship Management (SRM):

Supplier Relationship Management (SRM) is a pivotal aspect of strategic sourcing, emphasizing the establishment and sustenance of strong and collaborative partnerships with suppliers. At the core of SRM is a deep understanding of the capabilities and limitations of each supplier within the network. This involves not only assessing their production capacities and product quality but also understanding their financial stability, ethical practices, and overall reliability.

Effective Supply Chain management goes beyond a transactional approach to procurement; it involves fostering open lines of communication between the buyer and supplier. Regular and transparent communication helps in building trust and facilitates a collaborative environment. Through ongoing dialogue, both parties can address challenges, share insights, and work together to identify opportunities for improvement. This collaborative spirit is crucial for adapting to changing market conditions and evolving business needs.

Risk Management:

In the context of today’s globalized marketplace, supply chain disruptions are practically unavoidable due to various external factors. Strategic sourcing serves as a proactive and systematic approach to anticipate, identify, and mitigate potential risks that could adversely affect the supply chain. These risks encompass a broad spectrum, ranging from geopolitical events and natural disasters to fluctuations in supplier financial stability.

A key aspect of strategic sourcing is the proactive identification of potential risks. This involves a thorough assessment of the external environment and an understanding of the geopolitical landscape, regional vulnerabilities, and the historical patterns of natural disasters. By conducting a comprehensive risk analysis, organizations can pinpoint potential threats that might disrupt the supply chain and take preemptive measures to address or mitigate them.

Moreover, strategic sourcing goes beyond mere identification and incorporates mitigation strategies. This involves implementing measures to reduce the impact of identified risks or developing contingency plans to navigate through disruptions effectively. For instance, diversifying the supplier base, having alternative transportation routes, or maintaining strategic stockpiles are strategies that can be employed to enhance resilience in the face of unforeseen challenges.

The ultimate goal of these risk management efforts in strategic sourcing is to ensure business continuity. By being proactive and prepared, organizations can better navigate disruptions, maintain the flow of goods and services, and minimize the negative impact on operations. This resilience in the supply chain is crucial for sustaining customer satisfaction, meeting market demands, and safeguarding the overall health of the business.

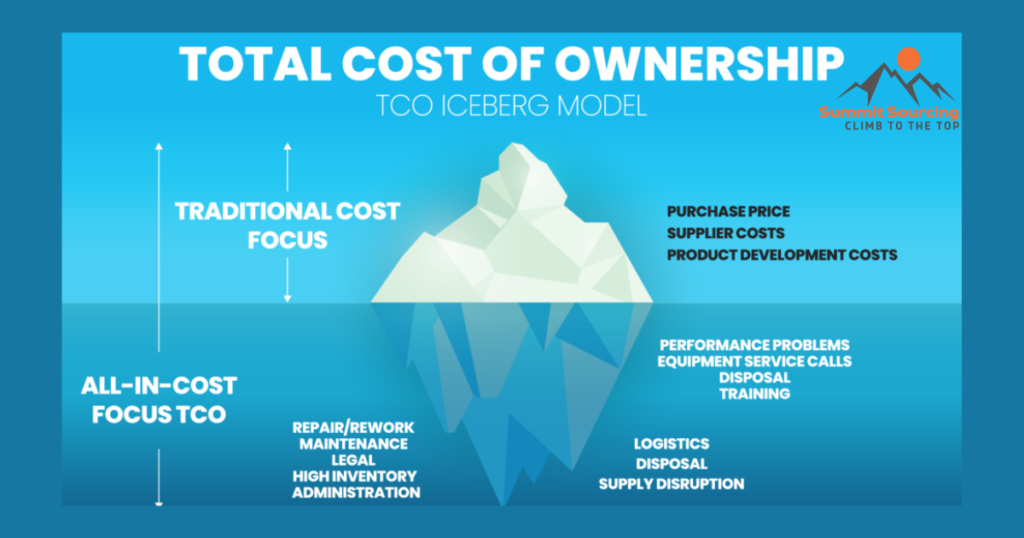

Total Cost of Ownership (TCO) Analysis:

Total Cost of Ownership (TCO) analysis is a fundamental component of strategic sourcing that diverges from the conventional approach of concentrating solely on the upfront purchase cost. Traditional procurement tends to emphasize securing goods or services at the lowest initial price, often overlooking the broader expenses incurred throughout the entire lifecycle of the product or service. Strategic sourcing, on the other hand, adopts a more comprehensive perspective by taking into account all costs associated with owning and utilizing a product or service.

In a TCO analysis, various factors are considered beyond the initial purchase cost. This includes but is not limited to ongoing maintenance expenses, transportation costs, and the costs associated with the eventual disposal of the product. By incorporating these additional elements, organizations gain a more accurate and realistic representation of the true investment required over the entire lifecycle of the procured item.

The significance of TCO analysis lies in its ability to reveal hidden or overlooked costs that may have a substantial impact on the overall financial commitment. For instance, a product with a lower upfront cost may incur higher maintenance expenses over time, making it less cost-effective in the long run. Strategic sourcing, through TCO analysis, empowers organizations to make more informed decisions, considering both immediate and long-term financial implications.

By embracing TCO analysis as part of strategic sourcing practices, organizations can optimize their procurement strategies, aligning them with broader business objectives. This approach not only promotes financial efficiency but also contributes to better-informed decision-making, ultimately enhancing the overall effectiveness and sustainability of the supply chain. In summary, TCO analysis is a strategic tool that enables organizations to make procurement decisions that are not solely driven by upfront costs but consider the complete economic impact of their choices.

Supplier Diversity and Innovation:

Supplier diversity is a key aspect of strategic sourcing that goes beyond the traditional considerations of cost and efficiency. It involves a deliberate effort to engage with suppliers from diverse backgrounds, including those owned by minorities, women, veterans, and other underrepresented groups. Strategic sourcing recognizes that a diverse supplier base brings valuable perspectives, skills, and innovative solutions to the table.

One of the significant advantages of supplier diversity is its contribution to fostering innovation within the supply chain. Suppliers from diverse backgrounds often bring unique ideas and approaches to the procurement process. The collaboration between companies and diverse suppliers creates a dynamic exchange of knowledge and creativity. This diversity of thought and experience can lead to the development of new products, improved processes, and innovative solutions that might not have been possible within a more homogeneous supplier network.

Moreover, engaging with diverse suppliers aligns with principles of social responsibility. By actively promoting supplier diversity, organizations contribute to the economic empowerment of historically marginalized groups. This commitment to diversity not only enhances a company’s reputation as a socially responsible business but also supports broader societal goals of inclusivity and equality.

Companies that proactively embrace supplier diversity find themselves in a more advantageous position for long-term success. Beyond meeting ethical and social responsibility standards, these companies tap into a broader pool of talent and innovation. They are better equipped to navigate an ever-changing business landscape by leveraging the creativity and adaptability that arise from diverse perspectives. Ultimately, supplier diversity becomes not only a strategic business practice but also a pathway to sustained growth, competitive advantage, and positive social impact.

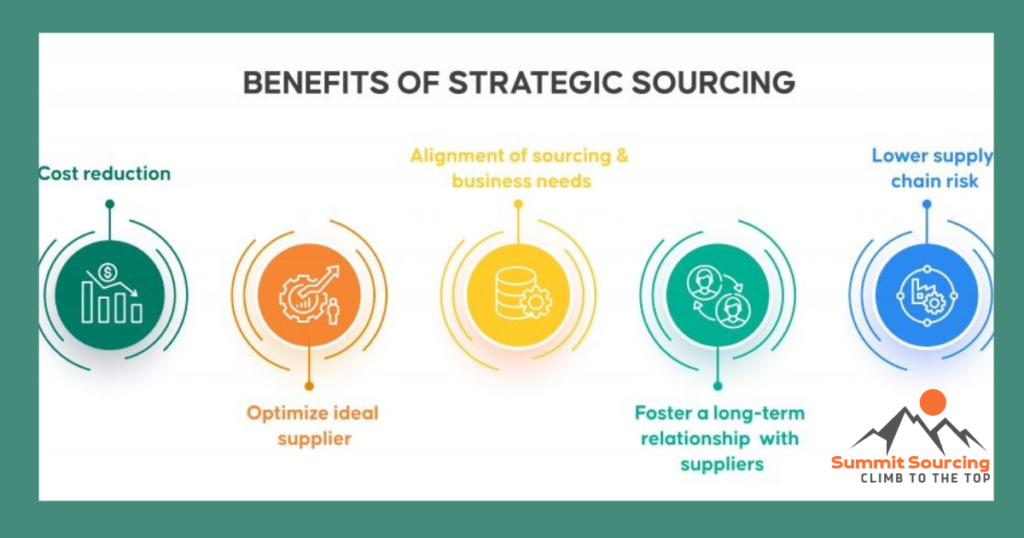

Benefits of Strategic Sourcing in Supply Chain:

Cost Reduction:

Cost reduction is a central objective in strategic sourcing, and organizations can achieve substantial savings by strategically evaluating the Total Cost of Ownership (TCO) and negotiating favorable terms with their suppliers. TCO analysis involves a comprehensive assessment of all costs associated with a product or service throughout its entire lifecycle, including acquisition, operation, maintenance, and disposal. This holistic approach ensures that hidden or long-term costs are considered, providing a more accurate picture of the actual expenses involved.

Negotiating favorable terms with suppliers is a crucial aspect of cost reduction. Through effective negotiation, organizations can secure lower prices, favorable payment terms, and other concessions that contribute to overall cost savings. This process often involves building strong and collaborative relationships with suppliers, where both parties work towards mutually beneficial outcomes.

The cost savings achieved through strategic sourcing enable organizations to reallocate resources to other critical areas of the business. Whether it’s investing in research and development, expanding market reach, or improving operational efficiency, the ability to redirect funds from reduced procurement costs can have a positive impact on overall profitability. This reallocation of resources allows organizations to stay competitive, respond to market demands, and make strategic investments that drive long-term growth.

In essence, the cost reduction achieved through strategic sourcing goes beyond simply cutting expenses; it becomes a strategic lever that empowers organizations to optimize their financial resources. By actively managing and reducing costs through TCO analysis and negotiations, companies can enhance their financial health, strengthen their competitive position, and create a foundation for sustained profitability and growth.

Improved Quality and Performance:

Strategic sourcing plays a pivotal role in elevating both the quality and performance of products and services within a supply chain. This improvement is achieved through meticulous supplier selection processes and the continuous monitoring of supplier performance. By implementing stringent criteria during the supplier selection phase, organizations can identify partners who not only align with their values and objectives but also demonstrate a commitment to delivering high-quality goods and services.

The ongoing monitoring of supplier performance serves as a quality assurance mechanism. Through regular assessments and evaluations, organizations can ensure that suppliers adhere to agreed-upon quality standards and consistently deliver products or services that meet or exceed expectations. This commitment to quality has a direct and positive impact on customer satisfaction. When customers receive products or services that consistently meet high standards, it enhances their overall experience and fosters a sense of trust and reliability.

Customer satisfaction, in turn, contributes to customer loyalty. Satisfied customers are more likely to remain loyal to a brand, make repeat purchases, and even become advocates for the business. In this way, strategic sourcing becomes not only a means to secure high-quality inputs for the supply chain but also a strategic driver for building and maintaining a satisfied and loyal customer base.

In summary, the emphasis on improved quality and performance in strategic sourcing is a proactive strategy that not only meets the organization’s internal standards but also directly impacts external perceptions. It aligns with the broader goal of fostering customer satisfaction and loyalty, ultimately contributing to the long-term success and sustainability of the business.

Enhanced Flexibility and Adaptability:

The cultivation of robust relationships with suppliers and the strategic implementation of risk management measures contribute to enhancing the flexibility and adaptability of the supply chain. When organizations establish strong connections with their suppliers, it fosters a level of trust and collaboration that is instrumental in navigating challenges and changes. This collaborative foundation allows for more effective communication and coordination, enabling the supply chain to respond swiftly to evolving circumstances.

Moreover, the integration of risk management strategies adds an additional layer of resilience to the supply chain. By identifying potential risks and implementing proactive measures to mitigate them, organizations are better prepared to handle disruptions and uncertainties. This preparedness translates into an increased capacity for the supply chain to adjust to unexpected market fluctuations, geopolitical shifts, or other unforeseen events.

In the dynamic and fast-paced landscape of today’s business environment, the ability to adapt quickly is paramount. Markets can evolve rapidly, consumer preferences may change, and external factors can introduce unforeseen challenges. A flexible and adaptable supply chain is better positioned to absorb shocks, adjust to new market conditions, and capitalize on emerging opportunities. This agility is not only a strategic advantage but also a crucial factor in ensuring the long-term viability and competitiveness of a business. In essence, the combination of strong supplier relationships and effective risk management fosters a supply chain that is not only resilient but also agile in the face of constant change.

Innovation and Competitive Advantage:

The integration of innovation into business strategies is pivotal for gaining a competitive advantage, and fostering collaboration with diverse suppliers serves as a catalyst in this pursuit. When organizations actively engage with a variety of suppliers, each bringing unique perspectives and expertise to the table, it creates an environment conducive to innovation. These diverse collaborations enable companies to tap into a wealth of ideas, insights, and approaches that might not be readily available within their own organizational boundaries.

Being at the forefront of industry trends and swiftly adopting new technologies are key components of leveraging innovation. By staying abreast of emerging developments and actively incorporating cutting-edge solutions into their operations, companies can position themselves as industry leaders. This proactive approach not only ensures relevance in a rapidly evolving business landscape but also allows organizations to offer products or services that are ahead of the curve. This, in turn, contributes significantly to building and sustaining a competitive edge in the market.

In essence, the nexus between innovation and competitive advantage is fortified through collaborative relationships with diverse suppliers. The continuous exchange of ideas and the integration of novel technologies derived from such collaborations enable organizations to not only keep pace with industry changes but also to outpace competitors, establishing themselves as leaders in their respective fields.

Conclusion:

In conclusion, strategic sourcing stands as a fundamental element in the realm of efficient supply chain management. It presents a holistic methodology for procurement that extends beyond the basic evaluation of costs. The essence of strategic sourcing lies in its emphasis on building and nurturing relationships with suppliers, actively mitigating risks, and fostering an environment conducive to innovation.

By adopting these principles, organizations stand to streamline their operations, cut down on expenses, and ultimately position themselves ahead in the dynamic and ever-changing business environment. In the face of globalization and the rising complexities associated with supply chains, strategic sourcing remains not just a choice but a strategic necessity for businesses committed to achieving enduring success. It is a proactive approach that empowers organizations to navigate challenges, capitalize on opportunities, and maintain a competitive edge in the marketplace.

CONTACT US for our services!